Bighorn sheep bows

Photo Gallery

Photo Gallery

Bighorn sheep bows.

Bighorn bows in the American West

The picture left is of a bighorn bow fragment found in Elko county Nevada. It was found in a large rock shelter. Date unknown. The belly is more rounded than the back. The back has been roughed for the sinew backing There is still a sinew wrap near the tip where the nock would have been. There is also evidence of a full backing and a dark substance that may have once been glue. The fragment is 22.3 cm long and 12 by 24.5mm in thickness and width. It may be quite old.

Bows made from the horns of the desert and Rocky Mt bighorn sheep were in use among many of the Plateau, Basin and plains tribes. By all accounts they were much desired and valuable possessions.

On the plains they were used by the Cheyenne, Crow, Sioux, Hidatsa, Mandan, Arikara, Gros Ventre, and although I have not seen one the Blackfoot were said to have them. Further to the west they were in use by the Flathead, Nez Perce, Shoshoni, and Paiute. Further south they were used by the Ute centered in the Colorado Rockies, and the Southern Paiute in Utah and Nevada.

The average length of these bows were about 32 inches or so. Horn and sinew can handle a great deal more bend than wood, so this size would handle the draw length of 20+ inches. Horn can handle a great deal of compression and sinew will do the same for the tension.

In George Bird Grinnell's book "The Cheyenne " He writes a bit about the bighorn bow. "Bows made of the horn of the mountain sheep were durable and very useful, and long ago many of these were possessed by the Cheyenne" He goes on describing how he heard they were made and adds that after they were backed with sinew they were "very strong and springy" The finishing of the bow was done by rubbing the sinew and horn with a buffalo rib to make it smooth and shinny . The tips were wrapped with sinew to hold the string and the sinew back was coated with burnt gypsum mixed with hide glue to whiten the back. He says this was done on many of the best bows, even of wood and sinew. In Encyclopedia of Native American Bows, Arrows, and Quivers Volume 2 by Steve Allely and Jim Hamm, p 166 has a Cheyenne bighorn bow. This one is 32 5/8" long. 1 5/16 wide at the grip, 1 1/8 at mid limb and 1/2" below the nock. This one has a buckskin wrapped handle ( Grinnell said this was standard on horn bows) and a 3 ply sinew string. Instead of being whitened, this one is blackened with melted pitch over the sinew. This also helps to waterproof the sinew, but in my experience the sinew takes some moisture from the sap and the reflex caused by the sinew is less, so the bow looses some power. In this same book he also has a sheephorn bow from the Crow. This one is 30 7/8", has a nice double curve shape, and measures 1 1/8 wide by 9/16 thick at the grip. 31/32 x 1/2 at mid limb, and 15/32 x 1/2 at the tip. The bow is circa 1830 and must have had a heavy draw.

Windriverhistory.org has a text called "Mountain Shoshone: The Sheep Eaters" In this Tom Lucas recreates the bows of this division of the Shoshone who once lived in the Yellowstone area. They were able to use the hot springs to soften the horn to make it easier to work and shape.

Left: Hidatsa with hornbow

In Laubins book "American Indian Archery", he devoted a chapter to the horn bow. He has 2 pages of ex ray cross sections and measurements. A Ute bow- 38" long 1 5/16 x 3/4 at the grip, 31/32 x 11/16 mid limb and 9/16x 15/32 below the nock. The Crow bow already mentioned. and a Nez Perce bow. 37 3/8" long, 1.5x 1 at the grip, 1.5 x 19/32 mid limb and 21/32 X 9/16 below the nock. The Ute bow is more than 50% sinew The Crow and Nez Perce are between 1/3 and 1/2. Most horn bows had a thick sinew backing. Horn can handle a backing of more than 1/3, while wood has problems at more than that

T M Hamilton's book "Native American Bows" has a lot of information about horn bows, including a newer appendix by Bill Holm on making sheep horn bows. Appendix 2 has hornbows from the Grayson collection. Dr Grayson also has a chapter in "The Traditional Bowyers Bible volume 2" about hornbows. Appendix 4 has descriptions of 7 sheephorn bows in the US National Museum. The curator notes that he thinks 4 of the bows are cow horn. This may be true but I think they are miss labeled and are bighorn. Bighorn bellies can look a little like cowhorn. The curator sad it must be cow horn as it is not buffalo horn.

There are 2 Sioux horn bows. 34.5" long, 1 1/8 x 3/4 at the grip, 1 1/16 x 17/32 at mid limb, and 7/16 x 3/8 below the nock. The bow is made of 2 horns connected at the grip. The horns were butted together and riveted with 2 iron rivets to a short piece of horn 8" long on the back of the bow. The other Sioux bow is 32". The heavy sinew back is covered with canvas. This made it hard to get accurate. measurements, but it is about 1" wide near the center. A Hidatsa bow is 36" long, 1 3/16 x 3/4 at the grip. 1 x 9/16 midlimb and 7/16 x 7/16 below the nock. This bow is spliced at the center by lapping one piece over the other 3 3/4 inches and riveting with 8 rivets. I have used this method and it works well. The Ute bow mentioned before is also in here. This Ute bow by the way was made of one piece of horn. Must have been a trophy horn!. In OT Mason's book "North American Bows Arrows and Quivers" he has drawings of double curved Sioux and Hidatsa bighorn bows.

There are also 4 Paiute bows listed. There are also 4 Paiute bows listed. 2 of these were collected by John W Powell during his travels in southern Utah and the Colorado River area in the 1860's. The first one is listed as cow horn also. This makes me almost sure that every bow he claims to be cow horn must have been mistaken and was bighorn, as the Paiutes had many bighorn and even elkhorn bows but not cow. It is spliced in the middle and the nocks are just a taper with a buckskin band below. It is unstrung and has a smooth curve. 30 inches long, 1 1/32 x 5/8 above the grip, 29/32 x 15/32 mid limb and 15/32 x 15/32 below the nock. The next one is 33" long, 1 1/16 x 9/16 center, 15/16 x 1/2 mid limb and 1/2 x 9/32 1 inch below the tip. The nocks of this bow were formed by sinew extending past the horn and curled up, just as the Miwok bows of California. The sinew is covered with pitch. The last one is listed as coming from the Digger Indians of California. Digger was also a slang name given to many Paiutes. It is sharply reflexed. Nocks are like above with sinew wrap. The bow is wrapped with fine sinew the entire bow. 33" long, 15/16 x 17/32 center, 7/8 x 7/16 mid limb and 15/32 x 5/16 below nock. Another Paiute horn bow in the Smithsonian is 31" long, width at handle- 1 1/8, 1" mid limb and 1/2" below the nock. It has a shallow c reflex and a buckskin handle. Perhaps the oldest surviving piece of Paiute horn bow came from a rock shelter excavation in Elko county Nevada near the Utah boarder. It is 22.3cm of the tip of a old bighorn bow. Very weathered but still has a sinew wrap and signs of more. It is 12 x 24.5 mm thick and wide. The tip is rounded and the cross section is half round with the flat back showing signs of sinew.

With the exception of the Comanche, It appears that most of the Numic or Shoshone/Paiute nations of the basin and plains used the horn bow. The Sheep Eater group of the Northern Shoshone were known for there fine sheep horn bows. These are the Indians of the Yellowstone and Wind River area in Montana and Wyoming. Archaeologists say it was these Shoshone who pecked the Dinwoody style petroglyphs that are found in this area. These are distinctive strange spirits or "Pandzoavits" usually around water. The large collection of Dinwoody petroglyphs on the Southern end of Stansbury Island on the Great Salt Lake show that this belief was also in the Salt Lake area of Utah, or at least used the island as a sacred site. Today it is on the shore of dry salt flats to the south, but as recently as 1869 those salt flats were water and a thin peninsula connected it to the Stansbury mountain range to the south. Historically, in there Yellowstone range They used the hot springs to make working and shaping the horn easier. In Loendorf and Stone's book "Mountain Spirit" they devote a chapter to these bows. In this chapter there is a sheep horn bow found in a cave in western Wyoming. This bow was dated to 1737. I believe it is 33" long and is made of 2 horns joined at the handle with a butt splice. The back of the bow has a thin 15cm long piece of horn under the sinew at the handle and there is evidence of one being on the belly at one time. There is also a as best said in the book "tongue depressor" at the handle splice. There is a x ray picture in the book that I can not explain in words. There are no rivits in this bow, so this tongue must have been some important device to keep this butt from pulling apart.

It is not known how long horn bows have been in use in the new world. The wooden bow came to be used around 200 AD in the area of horn bows. Many people believe that the western sinew backed bow and horn bow technology came to the new world from Asia. Brought here by sea going explorers before the time of Columbus.

There was an article written in Primitive Archer Magazine of a more than 200 year old composite horn bow from I think Turkey?. The author was eventually able to string it and bring it to near full draw. These bows will last and shoot many lifetimes of wood bows.

Horn Bow Construction

Anyone with a lot of patience, has experience with making sinew backed bows and has a understanding of the properties of horn should be able to make a horn bow.

The first thing to making a horn bow is finding horns. There are 3 types of bighorn sheep in the lower 48. Rocky Mt, Desert and California. All of these will make a great bow. The minimum size needed is about 23" along the outside curl. The longer the better, as you can cut through flaws and twists. A nice set of horns will run you about $500-2000. I've also used Alaskan Dall sheep and Canadian stone sheep horns. These are another native American sheep species with a range north of the bighorn. These horns are a little narrower but otherwise almost identical and usually run a couple hundred less for a nice set, if you can find them. I would caution against buying on ebay. There are many things that you have to avoid, bug damage, dry and cracked, etc.. It is best to inspect these yourself. A lot of horns also have a metal plug inserted by fish and game right where the bow would be. I have used mouflon sheep horns. They work and look similar but are thinner and so hard to make a powerful bow.

I have heard of people using a bandsaw on these horns to make a quick cut. If you are a bandsaw master go ahead. I use a hacksaw and go slow as to not ruin a $1000 set of horns right at the start. I can cut the strip off a 27" horn with a hacksaw in about an hour.

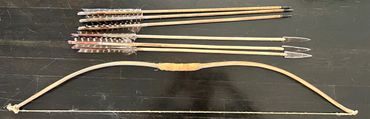

Photo Gallery

Horns, cut shaped strips, bow seasoning and finished bow.

Pencil line drawn for the hacksaw cut

The next step is removing most of the horn to end up with the strips to be used for the bow. To begin a rasp works well to remove a lot of the outside and inside of the horn. This is less messy than using a table sander at this point and work is almost as fast but takes more effort.

Photo Gallery

Reducing the outer horn to find flew free core. At this point a belt sander can be used, but be careful not to go too far and ruin a $800 set of horns. The best finish work is done with a knife, file and sandpaper. Go slow and check your work often. The final strips should be about 1/4" to 3/8" thick. If you have to remove a lot of horn to get through the flaws.

Unlike wood that should not have a sinew backing more than 1/3 that of the wood. A horn bow can be more than 50% sinew and many old ones were.

If you are lucky enough to have a horn longer than 35" you can use a single piece without a handle splice. The catch is a mount that big is hard to find for under $1500, so I will explain the handle splice.

After the horn is thinned to less than 1/2" it can be boiled and flattened. It should not be boiled for a long time as the horn will start to degrade after 10 minutes. Even after boiling the horn and clamping it to a form for days, it will eventually return a little twist from memory. To solve this a piece of tape is placed on the horn to cut a strait strip.

Photo Gallery

The horn strips being cut to rough shape, now the slow careful process of final shaping and fitting the handle splice begins.

I use a caliper to make sure both limbs are exactly the same size before backing with sinew.

Photo Gallery

When everything fits together perfectly boil the horn for 10 minutes and clamp it to a form to leave for a few days. Next make the two pieces one.

Most old bows of two pieces were spliced in 2 ways. 1 the lap splice. That overlaps for a few inches and is then riveted and wrapped with sinew. 2 A smaller lap or butt splice that was reinforced by a short section of horn on either side This is the long lap splice. The horns are fitted together perfectly then glued and then riveted with horn pins, copper or iron rivets

Smaller lap splice with two short sections of horn on the belly and back

Photo Gallery

A over built handle on a powerful bow before finishing and backing with sinew. This handle is a lap splice with two short sections of horn on the belly and back. The sections were grooved, glued and then riveted with 6 copper rivets. the copper rivet design is copied from a Nez Perce bow.

The bow before being backed with sinew. Notice the tiller is very uneven. This is tillered with heat. Not by removing horn as is done in wood bows.

Electric burner used to even the bend

Photo Gallery

This is as far as you want to bend the horn before it has a sinew backing

The horn must be washed , sanded and then grooved so the sinew can better adhere. Then a thin mixture of hide or sinew glue diluted to about 5%-10% is brushed over the bow till dry. This is repeated until the horn has a shiny look when dry.

Sinew is best applied in 3 layers. Each layer is 25-40 grams of dry processed sinew. I use a gram scale to weight the bundles to make sure each limb gete a equal amount. The first layer is applied. Then the second one week later and so on.

My Blog

Copyright © 2024 heartwoodbows - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.